Primary Crusher Wet Process Pan Mill

Product Details:

- Product Type Primary Crusher Wet Process Pan Mill

- General Use Industrial

- Material Cast Iron

- Weight (kg) 5700/6500 Kilograms (kg)

- Computerized No

- Automatic Yes

- Voltage 220-440 Volt (v)

- Click to View more

Primary Crusher Wet Process Pan Mill Price And Quantity

- 5000 USD ($)/Set

- 1 Set

Primary Crusher Wet Process Pan Mill Product Specifications

- 1 Year

- Yes

- Industrial

- No

- High Performance

- Cast Iron

- 5700/6500 Kilograms (kg)

- Primary Crusher Wet Process Pan Mill

- 220-440 Volt (v)

Primary Crusher Wet Process Pan Mill Trade Information

- Shanghai, Tianjin, Guangzhou, Ningbo

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C)

- 100 Set Per Month

- 30 Days

- Container

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO

Product Description

| Name | Unit | Parameter | ||

| | | MP165 | MP180 | MP200 |

| Wheel diameter | mm | 1600 | 1850 | 900 |

| Wheel width | mm | 500 | 700 | 700 |

| Loading power | kw | 45+2x2.2+1.1 | 90+2x3+1.1 | 132+2x4+1.1 |

| Wheel quantity | pce | 2 | 2 | 2 |

| Inner/ outer wheel weight | kg | 5700/6500 | 8500/11000 | 12000/15000 |

| Weight (incl. Motor) | kg | 52000 | 56000 | 70000 |

| Dimensions | m | 4x4x6.2 | 5.3x4.6x6.5 | 5.5x4.7x6.7 |

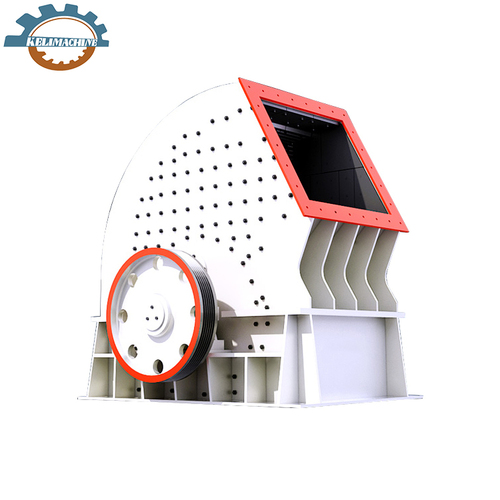

Wet Process Pan Mill (Primary crusher)

The wet wheel mill uses the relative movement between the rotating roller and the fixed grinding plate to crush, compact, compact, mix and homogenize the materials on the plate, and to achieve a certain humidity requirement. It is suitable for processing shale, clay and various raw materials mixed with industrial waste such as fly ash. It is a raw material processing equipment for brick and tile production line.

The batch material and water are added to the mill, and after being uniformly kneaded, the material is discharged by a discharge mechanism. In the mixing process, there are both agitation and extrusion, which can better exclude the air between the material particles, make the mixed mud material uniform, the surface of the particles is fully wet, and the mixing effect is good, but the particle size of the material is certain. The destructive effect. The wet mill is cumbersome, with low output and high energy consumption, but the quality of the mixed mud is good.

The wheel-type grinding operation mode is adopted: firstly, the electric motor drives the power to the speed reducer, and under the driving of the speed reducer, the torque is transmitted to the upper horizontal shaft through the large vertical shaft, and then transmitted to the grinding wheel through the tie rods installed at the two ends of the horizontal shaft. The driving force of the grinding wheel is generated, and the counterclockwise rotation movement is performed along the horizontal direction of the horizontal axis; the working wheel can revo lve around the large vertical axis of the wet mill, and can rotate around the central axis of the grinding wheel, and the grinding plate is fixed. The added one material is subjected to the pressing force from the weight of the grinding wheel in the mill, and the huge friction generated by the grinding wheel during the rotation and rotation of the grinding wheel is subjected to repeated extrusion, boring and grinding. Thoroughly smashed.

Main working parts: smashing and grinding

Wet grinding wheel mill according to process use (can handle raw materials with water content exceeding 15-16%), dry grinding and semi-dry grinding wheel mill (used when the water content of material is below 10-11%), crushing and mixing wheel Mill (for the crushing and mixing of different components of the material).

According to the operation method, the continuous wheel mill (continuous feeding and discharging) and the intermittent wheel mill (feeding and unloading intermittently). The wheel mill is divided into an iron wheel mill and a stone wheel mill according to the material of the wheel. The specifications of the wheel mill are expressed by the diameter x width of the wheel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+