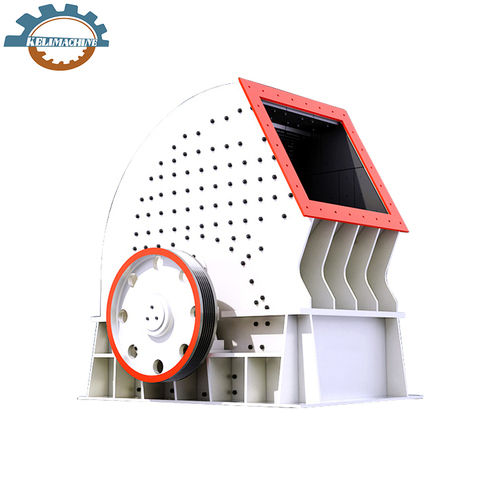

Mill Crusher Heavy Hammer Crusher For Stone

Mill Crusher Heavy Hammer Crusher For Stone Specification

- Product Type

- Mill Crusher Heavy Hammer Crusher For Stone

- General Use

- Industrial

- Capacity

- 50-90 T/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 220-440 Volt (v)

- Dimension (L*W*H)

- 1760X1700X1540 Millimeter (mm)

- Feature

- High Performance

- Color

- White

- Warranty

- 1 Year

Mill Crusher Heavy Hammer Crusher For Stone Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai,Tianjin,Ningbo

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 35 Days

- Packaging Details

- Container

- Main Export Market(s)

- Asia, Africa, Australia, South America, North America, Central America, Eastern Europe, Middle East, Western Europe

- Main Domestic Market

- All India

- Certifications

- ISO

About Mill Crusher Heavy Hammer Crusher For Stone

Technical Parameters of heavy hammer crusher

| Model | Feeder opening size(mm) | Rotor size(mm) | Input Size (mm) | Power(kw) | Capacity (t/h) | Overall dimension |

| KL-PCZ-0808 | 800X500 | 850X790 | 450 | 37X2 | 50-90 | 1760X1700X1540 |

| KL-PCZ-1308 | 850X800 | 1310X790 | 600 | 55X2 | 100-160 | 2818X2100X2390 |

| KL-PCZ-1510 | 1000X850 | 1500X950 | 700 | 132X2 | 160-210 | 3260X2370X2750 |

| KL-PCZ-1512 | 1210X900 | 1500X1160 | 750 | 160X2 | 220-350 | 3260X2580X2750 |

| KL-PCZ-1615 | 1500X1200 | 1650X1452 | 1000 | 200X2 | 350-500 | 3456X2915X3185 |

| KL-PCZ-2015 | 1500X1400 | 2000X1500 | 1200 | 315X2 | 500-800 | 3880X2990X3560 |

Product Description:

Brief Introdution of heavy hammer crusher:

Heavy hammer crusher is widely used in metallurgy, mining, chemical, cement, coal gangue, construction, sand, refractory material, ceramic and other industrial and mining enterprises, engaged in breaking and crushing the material in the operation. It is mainly suitable for crushing various soft and hard ore. whose compression strength is not higher than 320MPa (MPa),such as coal, salt, chalk, gypsum, blocks, limestone, etc.The main working part of hammer crusher is rotors with hammer. The rotors consist of main shaft, disk, pin shaft and hammers. The motor drives the rotors to rotate quickly in the crushing cavity. Raw materials enter the crusher through the feed opening and are stricken, impacted, cut and ground by the highspeed hammer to small size.

Applications of heavy hammer crusher:

Heavy hammer crusher is widely used in processing plants, refractory plants, cement, glass and other industrial sectors with medium hardness materials are finely ground. Can be used for dry or wet crushing, the material should be seeped before crushing , seepage is not allowed for dry crushing

Working principle of heavy hammer crusher:

The motor drives the rotor rotates at high speed in the crushing cavity. Material from the upper opening to feed into the machine, under hitting, impacting, shearing, abrasive and high-speed movement of the hammer and can be smashed. the crushed material smaller than the mesh size of the sieve which in the lower part of the rotor discharged , the larger one retained on the sieve and grinding continued to be hit by the hammer, and finally output through the sieve.

Features and advantages of heavy hammer crusher:

1.Latest technology design, strong structural, impact resistant.

2.heavy hammer crusher has large feed size, high yield, good grain shape

3.Super broken, coarse, medium and finely one pace reach the designated position.

4.The yield increased by 30% compared with the same needle flake (powder) more than 20% less, more energy efficient.

5.Hammer head, sieve plate with chromium manganese alloy materials, impact resistance, abrasion resistance stronger.

Price 1000 USD ($)/ Set

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 35 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Africa, Australia, South America, North America, Central America, Eastern Europe, Middle East, Western Europe

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mining Machine Category

Mill Crusher Powder Raymond Grinding Machine

Price 1000 USD ($) / Set

Minimum Order Quantity : 1 Set

Warranty : 1 Year

Product Type : Mill Crusher Powder Raymond Grinding Ma

Feature : High Performance

General Use : Industrial

Primary Crusher Wet Process Pan Mill

Price 5000 USD ($) / Set

Minimum Order Quantity : 1 Set

Warranty : 1 Year

Product Type : Primary Crusher Wet Process Pan Mill

Feature : High Performance

General Use : Industrial

JZM Mixer Machine for Building construction

Price 400 USD ($) / Set

Minimum Order Quantity : 1 Set

Warranty : 1 Year

Product Type : JZM Mixer Machine for Building construction

Feature : High Performance

General Use : Industrial

Industrial Branch Crusher

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Product Type : Industrial Branch Crusher

Feature : High Performance

General Use : Industrial