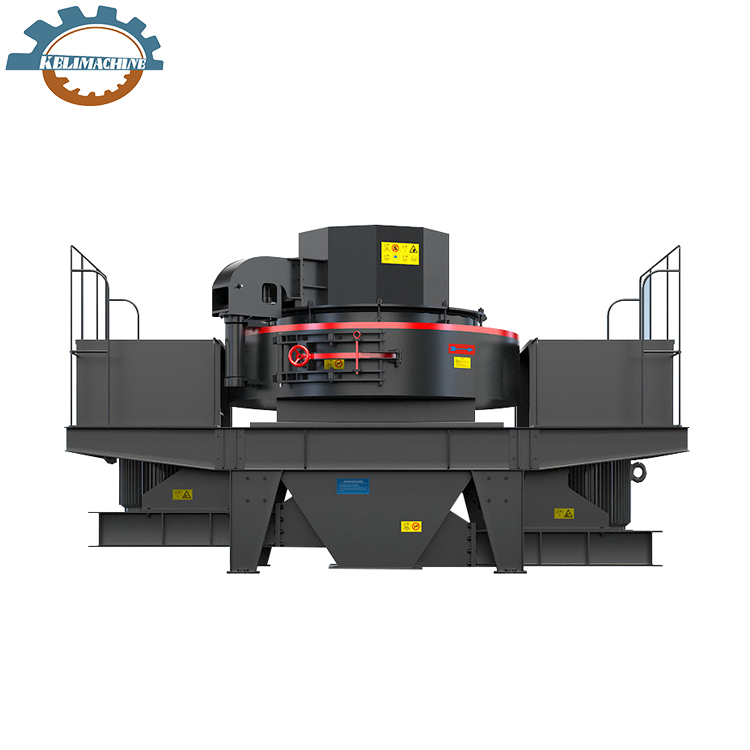

VSI Sand Artificial Making Crusher Machine

Product Details:

- Product Type VSI Sand Artificial Making Crusher Machine

- General Use Industrial

- Voltage 220-440 Volt (v)

- Dimension (L*W*H) 3700*2150*2100 Millimeter (mm)

- Feature High Performance

- Color Black

- Warranty 1 Year

- Click to View more

VSI Sand Artificial Making Crusher Machine Price And Quantity

- 1 Set

- 1000 USD ($)/Set

VSI Sand Artificial Making Crusher Machine Product Specifications

- Industrial

- 220-440 Volt (v)

- 1 Year

- VSI Sand Artificial Making Crusher Machine

- 3700*2150*2100 Millimeter (mm)

- High Performance

- Black

VSI Sand Artificial Making Crusher Machine Trade Information

- Shanghai, Tianjin, Guangzhou, Ningbo

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Western Union Letter of Credit (L/C)

- 100 Set Per Month

- 35 Days

- Container

- Asia Western Europe South America Central America Middle East Australia North America Eastern Europe Africa

- All India

- ISO

Product Description

VSI Series Vertical Shaft Impact Crusher (New Type Sand Making Machine) is a high level sand making equipment developed by our company after several technical improvements based on the introduction of advanced technology from Germany and the actual situation of domestic sand making production. This equipment is especially suitable for providing high-quality sand and gra vel aggregate for high-rise buildings, highway (railroad) construction, municipal engineering, large-scale water conservancy facilities, concrete mixing stations and many other fields.

Compared with similar products, VSI new type sand making machine has higher output, good product grain shape and spends less money on use. The machine is specially designed to provide high-quality sand and gra

vel aggregate for highway, high-speed railroad, high-rise building, municipal, hydro power dam construction, concrete mixing plant, and is the preferred equipment in the field of artificial sand making and stone shaping.

The product has excellent grain shape - the product is cubic, with good grain shape, reasonable grading and adjustable fineness modulus;

Working Principle

VSI sand making machine utilizes the advanced selective crushing and disintegration crushing principle, which directly applies enough kinetic energy to the material and converts the kinetic energy into the crushing energy required to overcome the material through impact and crushing. The material is basically broken along its natural texture surface and disintegration surface, with good grain shape and low self-consumption. The machine is capable of realizing the conversion of the two working principles of "stone hitting stone" and "stone hitting iron".

VSI series sand making machine adpots high-speed movement of materials mutual self-broken and friction between materials to crush.This series of equipment is not only crushing stone, making sand and also playing shaping role with the finished products.

The material falls into the feed hopper, through the center feed hole into the high-speed rotation of the dumping wheel, in the dumping wheel is rapidly accelerated, and its acceleration can be tens of times the acceleration of gravity, and then high-speed from the dumping wheel shot, the first with the rebound after the free fall of another part of the material impact, and then together with the impact of the material lining layer (stone to stone) or counterattack block (stone to iron) on the rebound diagonal upward impact to the top of the vortex chamber, and change its The direction of movement, deflection downward movement, and with the impeller channel launched from the material impact to form a continuous material curtain. In this way, a piece of material in the vortex crushing chamber by two to several times impact, friction and grinding crushing effect. The crushed material is discharged from the lower discharge port.

Center feed with ring-shaped waterfall feed: the material falls into the feed hopper, and then fall through the ring-shaped hole, is divided into two shares of material by the distribution plate, one by the distribution plate into the high-speed rotation of the dumping wheel, and the other from the distribution plate around the fall. Into the dumping wheel material, in the dumping wheel is rapidly accelerated, its acceleration up to tens of times the acceleration of gravity, and then high-speed injection from the dumping wheel, first with the other part of the material from the distributor around the free fall impact crushing, and then together with the impact to the vortex cavity vortex liner, the material liner rebound, diagonally upward to the impact of the vortex cavity to the top, and then to change the direction of its movement, deflection downward movement, and with the impeller channel from the impact of material launched out to form a continuous flow. And then it collides with the material launched from the impeller channel to form a continuous material curtain. In this way, a piece of material in the vortex crushing cavity by two to several times the rate of impact, friction and grinding broken. The crushed material is discharged from the lower discharge port.

Outstanding Advantages

1. Stone hitting iron crushing cavity, higher crushing efficiency

2. Deep cavity rotor design, greater throughput

3. Hydraulic cover opening device, convenient access and easy maintenance.

4. Thin oil lubrication program, providing a greater range of speeds

VSI sand making machine is widely used for fine crusher and coarse grinding of metal and non metal ores, cement, refractory material, grinding material, glass raw material, building aggregates, artificial sand and all kinds of metallurgical slags. It is especially suitable for medium hardness materials, high hardness materials and corrosion resistance materials, such as carborundum, emery, magnesia etc.

VSI Sand making machine is the latest product of authoritative experts from both home and abroad,connecting with quarry,mining present working conditions.

Application: 1. It is used for producing building aggregate, concrete, aggregate for road surface and roadbed, asphalt concrete and cement concrete. 2. It is also used for sand making and shaping in the field of engineering such as water conservancy, hydroelectric power, high-class highway, high-speed railway, passenger special line, bridge, airport pavement, municipal works and high-rise buildings. 3. It is used widely in many industries such as building materials, metallurgy, chemical engineer, mining, refractory materials, cement etc. 4. It is used for producing glass raw materials quartz sand and other high purity materials. pebble, limestone, granite, basalt, diabase, andesite, etc

Product Details

The raw material is high strength cast iron, with good mechanical property, as well as good ability of absorbing the energy of crusher's vibration. It's a great help to make the rotation of main shaft running steady, which can continuously stable the output of your crusher. The heat treatment of tempering is applied to release the internal stress. It's a great help to prevent the part's dimension change in the daily operation of your crusher. It obviously can prolong the life of your crusher. The final machining is carried by CNC machine to ensure each dimension tolerance, which helps to make your assembly easy and fast, to improve the efficiency of your production and maintenance.

| Model | KL-VSI-7611 | KL-VSI-8518 | KL-VSI-9526 | KL-VSI-1140 | KL-VSI-1145 | |

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 490-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2278 | 5000*2700*3300 | 5100*2790*3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |||||

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw | ||||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+