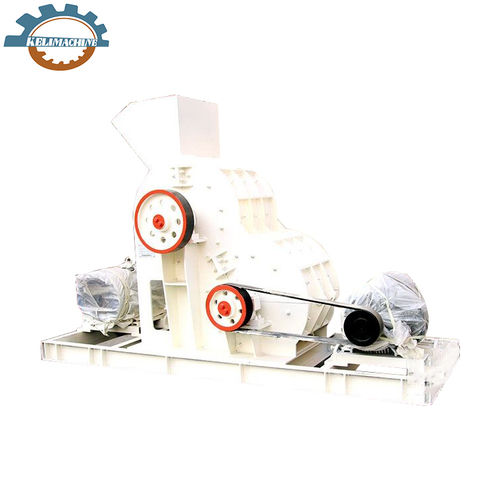

Stone Hammer Crusher Machine 30T Capacity

Stone Hammer Crusher Machine 30T Capacity Specification

- Product Type

- Stone Hammer Crusher Machine 30T Capacity

- General Use

- Industrial

- Material

- Cast Iron

- Capacity

- 10-30 T/hr

- Computerized

- No

- Automatic

- Yes

- Voltage

- 220-440 Volt (v)

- Feature

- High Performance

- Color

- White

- Warranty

- 1 Year

Stone Hammer Crusher Machine 30T Capacity Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai,Tianjin,Ningbo

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 35 Days

- Packaging Details

- Container

- Main Domestic Market

- All India

- Certifications

- ISO

About Stone Hammer Crusher Machine 30T Capacity

Hammer Crusher

Two-stage crusher work, under the double motor drive, each string of high-speed rotating at the same time, the two sets of rotor

cavity of the material in the machine immediately through superior rotor to crush by rapid rotation of the lower rotor hammer head

again finely, lumen material rapid collision each other, each other when the fans broken, achieve hammer powder, the effect of

powder material, form the discharging coal particle size less than 3 mm. The granularity of the material produced by the two-stage

mill can fully meet the requirements of brick manufacturers as internal combustion brick.

| Model | KL-2PC 600*600 | KL-2PC800*600 | KL-2PC1000*800 | KL-2PC1200*1000 | KL-2PC1400*1200 | KL-2PC1600*1400 |

| Max feeding size(mm) | 100 | 120 | 160 | 200 | 200 | 200 |

| Discharging size(mm) | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 | 0-3 |

| Processing capacity(t/h) | 10-30 | 18-55 | 22-90 | 30-120 | 40-140 | 50-180 |

| Motor power(kw) | 22+22 | 45+55 | 55+75 | 90+110 | 132+160 | 160+200 |

Double-stage crusher, also known as double rotor hammer fine crusher, is a new type of raw material crusher, the machine overcomes the raw material moisture content of large bonding grate bottom, not easy to discharge the defects, with high production efficiency, good crushing effect, etc., the machine is suitable for calcite, limestone, brick and tile factory slag, slag, slag, shale, coal gangue, construction waste, building waste, such as crushing materials, solving the problem of gangue, cinder for brick factory, additives, internal fuel; gangue, shale production of standard bricks, hollow bricks, high moisture material crushing problems. Additives, internal fuel; with gangue, shale production of standard bricks, hollow bricks high moisture material crushing problems. The machine is equivalent to two hammer breakers into one, a reasonable combination of a whole, two sets of rotors used in series.

Working Principle

Double rotor two continuous crushing, no sieve device, all kinds of wet slag can be crushed, both water fishing out can also be crushed at any time, there is no bonding blockage phenomenon, to control the size of the material only need to adjust the gap between the crushing hammer head can be. General crusher, because the material in the crushing cavity caused by blockage, resulting in increased wear and tear of the relevant parts, this series of crusher can avoid the above phenomenon. High-alloy wear-resistant hammer head: the hammer head is used in combination with the hammer shank, only the hammer head is changed, not the hammer shank. Shift gap technology, the hammer head does not need to be repaired after wear and tear, move the position for repeated use, a hammer head can be used on top of three sets of hammers. Crusher bi-directional rotation, through the continuous iso-shift bi-directional operation mode, can make the hammer head and crushing tooth plate between the uniform wear, reduce the frequency of downtime to replace wearing parts. Suitable for fine crushing of brittle materials, no clogging, less dust, low noise. Easy to install, greatly improving the freedom of the equipment. Quick maintenance, the upper side of the crusher side door can be reversed to open, which makes the maintenance of the crusher and the replacement of wearing parts become faster and more convenient, shortening the maintenance time.

Price 1000 USD ($)/ Set

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 35 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mining Machine Category

Iron Ore Drying Cement Rotary Kiln Machine

Price 3000 USD ($) / Set

Minimum Order Quantity : 1 Set

Feature : High Performance

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : Iron Ore Drying Cement Rotary Kiln Machine

sand screening machine with conveyor belt

Price 3000 USD ($) / Set

Minimum Order Quantity : 1 Set

Feature : High Performance

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : sand screening machine with conveyor belt

KL-701-1E Hand Push Crusher For Cattle Feed

Price 499 USD ($) / Set

Minimum Order Quantity : 1 Set

Feature : High Performance

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : KL7011E Hand Push Crusher For Cattle Feed

portable sand screening machine

Price 3000 USD ($) / Set

Minimum Order Quantity : 1 Set

Feature : High Performance

General Use : Industrial

Voltage : 220440 Volt (v)

Product Type : portable sand screening machine